7 Steps to Reopening

When the COVID-19 crisis arrived in the US, it was clear that, because of the virus' airborne contagion nature, that PPE (personal protective equipment) would be needed in healthcare centers and for anyone who would be in touch with other people. And given the many supply shortages (and long lead times), CPA Co-op wants to make sure our members and participants have enough masks, sanitizer, thermometers to be able to open safely. Our reopening blog series is a synthesis of all that we’ve learned from our research and conversations with members and participants.

Earlier this month, the team at CPA Co-op issued a survey to learn more about how community organizations were approaching reopening and PPE procurement. This survey, coupled with extensive research and conversation with suppliers and decision makers, offers our cooperative a unique perspective on the reopening landscape. Here’s what we’ve learned:

As of 6/1/2020 state health bodies have not given official guidelines on how schools / mass congregation events should be conducted moving forward. CPA Co-op’s expertise is in procurement. This is based on our best thinking and the signals we’ve gotten through CDC and FDA. Always consult the CDC and local health officials when finalizing your organization’s post-COVID 19 strategies.

Having said this, based on the signals we have been receiving from state governments, it is likely that we will all have to treat PPE (or at least face coverings) as a new staple in our lives outside of home. This leads us into the next step;

CDC Guidelines on Reopening the Economy:

https://www.cdc.gov/coronavirus/2019-ncov/community/organizations/businesses-employers.html

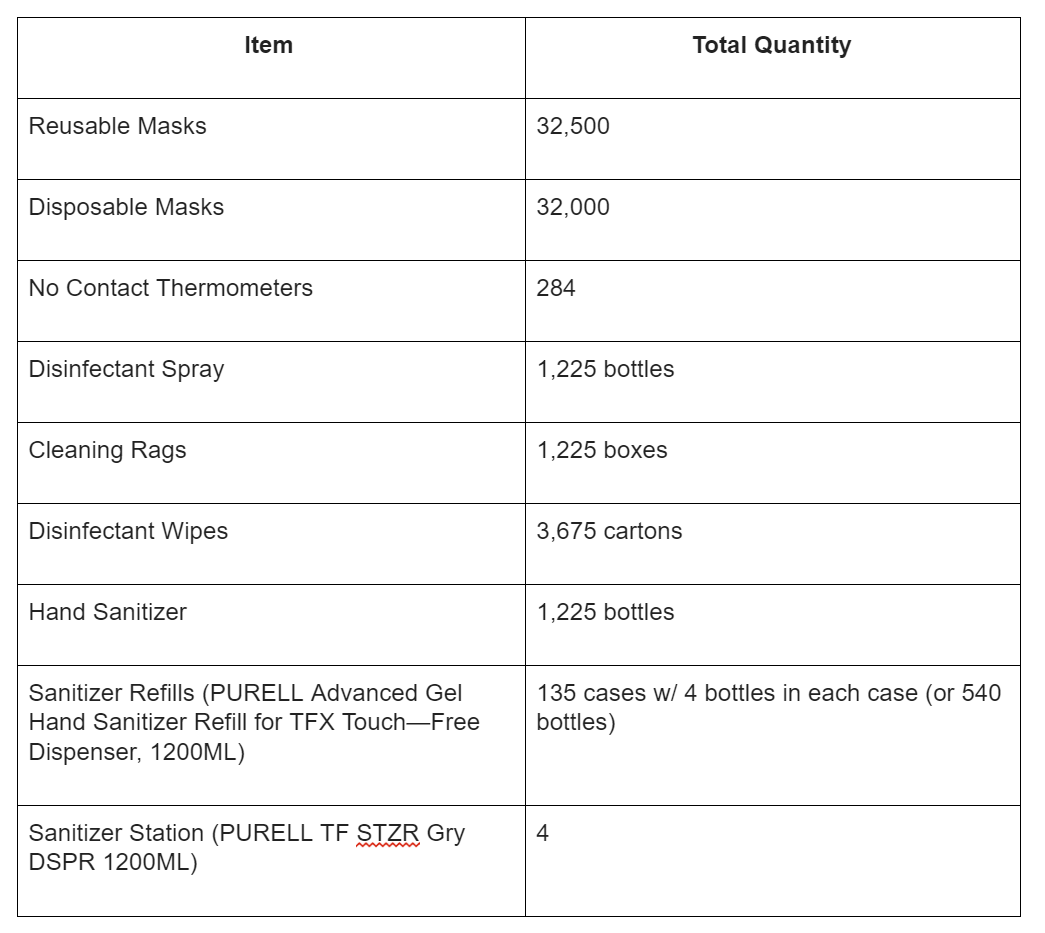

To help you get started on the math, consider the following case study from one of CPA Co-op’s largest member owners and local charter school network. Their initial assumptions are:

They have 5,000+ students across 15+ schools

They are hoping they'll be headed back to school on August 31st.

How might you estimate # of masks to buy?

This school's current thinking:

2 reusable masks per each student, teacher, and staff

Change out 2x per year

In other words 4 masks for each of their 8,000 students, teachers and staff

Plus spares so about 32,500

Costs range $2-5 per mask

Disposable masks for visitors -- about 2,000 visitors per semester - 4,000 per campus (7 campuses + central office = 32,000)

Costs range $0.50 - $1.50 per mask

For more on masks, stay tuned for part two of CPA’s reopening blog series: “Myths, Masks, and Misinformation.”

Congregations and smaller community institutions may consider thermometer stations at the entrances of their buildings. Disinfect sprays, rags, and sanitizers are also important to have on hand.

How many "no contact" thermometers to buy? Here is how one of our members approached it:

Each grade level receives 3

Operations team will have 10 at each campus for staff, visitors, etc

ABC School is estimating 45 at each of their 7 campuses + 5 for headquarters

Costs range $40-100 per "no contact" thermometer

Then, in addition to the supplies that janitorial / cleaning company provides, they also want to purchase:

Clorox wipes - 12 pack per month per classroom + 24 pack per office / year

Lysol spray bottles: Each space / office X 12/year + Classrooms X 24/year

Rags - (2000 per campus- 1 per month x 80 Classroom/Offices) They can be washed

Paper Towels - Early childhood & Elementary will need the most. Start with 12pack per month per classroom + Offices 24 pack per year

Sample Phase 1 Order: (for 5,000 students and staff across 15+ schools)

Hand Sanitizer: Stations or Bottles? Both?

For stations, this School's initial thinking had been one by every water fountain + large spaces would 3-4 each + by every main entrance and OM desk (2 each) + 4 per hallway.... Then they began realizing the need to pivot away from branded hand sanitizing stations and opt for generic hand sanitizer stations that could use different kinds of gels, simply because typical brands have not been as available.

Costs range $7 to 15 per 16 Oz Hand Sanitizer pump

CPA Co-op is actively working to find values-aligned providers and pricing that is 30-50% lower than what they had gotten quotes for on their own.

How much might it cost for Phase 1 for this School?

This is what really surprised me. Initial quotes for all these supplies came in around $275,000 for the 6,000 students for this Phase 1 purchase. That's about $45 per student.

The good news is by aggregating volumes from multiple customers and vetting more than 20 potential suppliers, CPA was able to find many items at prices for 30-50% BELOW what this School had initially gotten quoted on their own.

What are the considerations with choosing suppliers?

What is the shipping lead time for each item? (In some cases it's a few days, in other cases it's 6-8 weeks...)

Can you hold onto our items at your warehouse?

If so, for how long?

Is there a cost to hold onto our items?

Would you be able to ship to different locations (i.e. we have 8 locations)?

If so, is there a shipping fee per location?

If you are able to hold onto our items and then ship to different locations when we reopen, is there an additional shipping fee?

What are the payment terms? Do you require a deposit in order to place an order?

Product Quality / Types

Who the manufacturers are?

Mask comfort, color, sizes...

Reach out to CPA Co-op’s Communications Director Lauren Greenspan (lauren@cpa.coop) for a free consultation on how to approach messaging reopening with your audience and stakeholders.

DISCLAIMER

These estimates are one school's very quick early thinking about how much is needed. They are updating their thinking as they learn more. We all are. In the face of uncertainty, our hope is that these estimates might help prompt your own thinking for your environment.

Are these steps helpful? Download the full 7 Steps to Reopening Infographic to share with your organization.

Another Purchase in July and the Fall

In July we’re thinking of another purchase and we’ll likely know what the state bodies are recommending. Coupling that with the fact that we’ll have experience to adjust our assumptions based on what we’re actually going to need according to regulations.

And then the Fall, a lot of these institutions will get a sense of their actual burn rate of these supplies. In the fall we might do another purchase, adjusting to their burn rate when institutions know how quickly they are going to need to adjust.